- Homepage

- Application

- Brand

- Accuair (26)

- Accuair Suspension (27)

- Airmaxxx (92)

- Audiocontrol (38)

- Autel (35)

- Autel Robotics (43)

- Chassis Tech (31)

- Cognito (45)

- Firebird Industrial (47)

- Flowline (32)

- Huepar (25)

- Hunter (25)

- Kryptonite (56)

- Launch (86)

- Mercedes-benz (91)

- Next Level Racing (26)

- Perfect Fit (20)

- Superlift (20)

- U`king (91)

- Zone Offroad (20)

- ... (2564)

- Item Height

- Item Length

- Material

- 100% Brand New (2)

- Abs (8)

- Abs Plastic, Copper (2)

- Abs+plastic (3)

- Abs, Plastic, Pvc (12)

- Alloy Steel (40)

- Aluminum (9)

- Glass (3)

- Iron (3)

- Kunststoff (2)

- Metal (34)

- Metal & Glass (12)

- Metal, Plastic (16)

- Plastic (47)

- Plastic Composite (17)

- Plastic, Metal (5)

- Polypropylene (6)

- Stainless Steel (21)

- Standard (2)

- Steel (16)

- ... (3180)

- Type

- Amplifier (9)

- Camera (12)

- Canister / Cylinder (14)

- Ceiling Fan (18)

- Console (17)

- Control Arm Kit (17)

- Controller (34)

- Dehumidifier (11)

- Drone Camera (22)

- Espresso Machine (15)

- Ground Search (10)

- Hearing Aid (12)

- Kit (72)

- Level Controller (17)

- Moving Head Light (17)

- Preamplifier (12)

- Tower (15)

- Trail Camera (10)

- Upright (29)

- Wet / Dry (23)

- ... (3054)

ANCEL AJ400 GDI Fuel Injector Cleaner Tester Ultrasonic Nozzle Cleaning Machine

ANCEL AJ400 GDI Fuel Injector Cleaner Tester Ultrasonic Nozzle Cleaning Machine. Why do we have to clean injectors? After the car has been driven for a period of time, certain deposits will form in the fuel system, clogging the injectors. Clogged injectors can seriously affect the performance of the car.

The main purpose of cleaning injectors is to improve the atomization effect of gasoline, increase the combustion efficiency of gasoline and reduce fuel consumption. ANCEL AJ400 GDI Car Fuel Injector Tester Cleaner Car & Motorcycle 4-Cylinders Ultrasonic Heating Cleaning Machine Cleaner Tools. ANCEL AJ400 GDI injector cleaner & tester uses ultrasonic technology and microprocessor fuel pressure control cleaning and testing technology to quickly remove carbon from the vehicle fuel system, and test leaking, uniformity, inbreath of injectors, so that the injectors can discharge fluid more quickly.

The machine is the necessary and preferred equipment for the automotive serving and maintenance, research, and teaching training departments. This product has two versions, 110V US plug and 220V EU plug, please indicate the version you need.

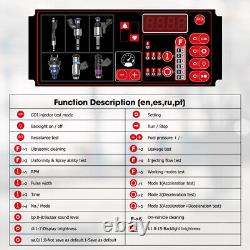

Ultrasonic cleaning: To clean injectors to remove carbon deposition completely. Resistance test: To test the resistance of the fuel injector. Uniformity/spray test: To test the uniformity of injection quantity of each injector and monitor the spray status of each injector. With the help of the backlight.

Leak test: To test the sealing and dribbling conditions of injectors under system pressure. Injection flow test: to check the injection quantity of the injector in 15 seconds of constant injection. Working modes test: To test injectors in different working conditions. In-Vehicle Cleaning: Coming with a variety of disassembly-free cleaning connectors, the device can be used to perform in-vehicle cleaning and maintenance for various vehicle models. Low-resistance injector test function: Through the dedicated motherboard, support long and full low-resistance fuel injector test, such as 1 ohm. Multiple item settings: Set different device parameters, including ringer sound level, screen brightness and backlight brightness.Version information: To check the current device software version information. This equipment supports testing of various GDI injectors.

Support long GDI injector detection, such as for Mercedes-Benz and for BMW. Support the resistance measurement of the fuel injector to know the performance status of the fuel injector. The special structure design makes the disassembly and assembly of the fuel separator more efficient and quicker. The device is very small and light and easy to move. It is currently the smallest full-function test equipment for GDI injectors.

The machine has a strong ultrasonic cleaning ability, which can remove carbon deposits and impurities on the fuel injection nozzle to the greatest extent. Adopting humanization design can make the system pressure fast restored to the default values. Recommended to carry out the complete cleaning and testing procedures as the following order. Before any operation, choose the correct injector type for proper operating. With the indicator light ON for GDI injectors.For general top-feed or side-feed injectors, no need to press this key. GDI Fuel Injector Cleaner & Tester. It can clean and test not only standard injectors but also GDI injectors, such as for Mercedes-Benz, BMW, Audi, Porsche, Ford, and other direct injection engines. 1 Connect one end of the resistance measurement line to the interface on the right side of the device, and the other end to the two electrodes of the fuel injector.

2 Start the machine, and press the key. The resistance value will be displayed on the screen. 3 If needed, measure several times to confirm the measured value. 4 After the measurement is completed, remove the fuel injector and the resistance measurement line.It works by sending an ultrasonic vibration signal to the injector through the pulse signal cable, which causes a strong vibration of the carbon inside and thus enables more thorough cleaning. 1 Place the injector/pump which has gone through surface cleaning in the launder. 2 Add enough injector detergent into ultrasonic cleaner so that the liquid level is about 20mm above the needle valve of injectors / whole pump. 3 Plug the pulse signal wire to injector / pump respectively. 4 Select ultrasonic cleaning function and then set the time.

5 Press RUN key to start the procedure. 6 Turn on the ultrasonic cleaning switch on the left side of the machine. 7 When the time is up, it will stop automatically as the beeper rings. 8 Turn off the ultrasonic cleaning switch on the left side of the machine after cleaning procedure. 9 Take the injector / pump out of the launder and wipe them with a dry soft cloth. Get ready for next operation. Uniformity test is to find out the difference of the injectors injecting at the same working condition. This test can indicate the comprehensive influences on the injector caused by electrical nature, bore variation and clogging. Ability test is to inspect the spraying performance by observing the injectors.Installing and testing procedures for injectors. 1 Choose a proper adaptor according to the injector type and mount it to the fuel separator.

2 Install the injectors in forward direction Apply a little lubricating grease on the O-ring. 3 Install the fuel separator with injector onto the plate of the test tube. 4 Connect the injector pulse signal wire. 5 Before doing this test, drain the test liquid from the measuring cup if there is any. 6 Select Uniformity/Sprayability test function, set corresponding parameters (consult the appendix for pressure setting, consult vehicle manuals for other parameters as needed), and then press RUN key to start the test.

7 When the test is completed, the equipment will auto stop with the ring of the buzzer. Leakage test is to inspect the sealing conditions of the injector needle valve under system pressure and to find out if the injector is dribbling.Installation refer to Uniformity/ Sprayability Test. 1 Before doing leakage test, please drain the rudimental residual test liquid from the measuring cup. 2 Select Leakage Test function and press Run key to start. 3 When the test is over, the equipment will automatically stop and the buzzer will ring simultaneously. Injecting flow test is to check if the injecting flow in 15 seconds meets the specifications for injecting amount.

The deviation reflects the wear or clogging in the injector, instead of electrical parameter variation. 1 Before this test, drain the test liquid from the measuring cup if there is any. 2 Choose Injecting Flow Test function and press Run key to start the test. Adjust the fuel pressure by pressing + or - key according to the injector specification.

3 When the test is over, the equipment will stop automatically at the ring of the buzzer. Working modes test contains three working status simulation tests(Acceleration, Deceleration, Acceleration+ Deceleration test). This function can test more comprehensive performance of injectors by simulating the various engine working conditions. 1 Before the test, drain all the test liquid in the measuring cups if there is any.2 Select Modes function and choose the mode needed, then press Run key to start the test. 3 Adjust the fuel pressure by pressing + or - keys. 4 When the test is over, the equipment will auto stop at the ring of the buzzer. It works by sending an ultrasonic vibration signal to the injector nozzle through the pulse signal line, which makes the stubborn carbon deposit jitter strongly and removes more thoroughly. Clean injector's outside with gasoline or cleaning liquid before turning on the machine.

Putting injectors in ultrasonic bathtub after the outside of injector is free of dirt. Turn on ultrasonic system, allowing the ultrasonic energy to dislodge any particles even build-up inside the injectors. Fix injectors on the machine. Test injectors for resistance, shorts, and current draw.

Perform leak test, spray pattern, and flow rate testing on flow bench. Power supply: AC110V±10% or 220V±10%. No open flames within 2m. Fuel tank capacity: 2000 ml. RPM range: 100~9900rpm, step:10rpm. Time range: 5~300s, step:5s. PWM pulse width: 0.1~25ms, step: 0.1ms. Dimensions: 355mm (length) × 350mm (width) × 380mm (height). Otherwise an Unpaid Item case will be opened to you. We have warehouse in USA, UK, HongKong, Australia, Russian, Germany and China warehouse. If you do not receive your order in the estimated time. We would do our best to serve you solve the problem. That you will be able to access every module or use every piece of cd/dvd software. Compatibility varies due to variations in the cars modlue or availabilty of year it released from original factory. Don't take charge to complete clearance. Please do not hesitate to leave us your. If you are happy with your shopping. ANCEL specializes in automotive intelligent diagnostics, detection and analysis systems, and automotive-related products for mechanics, repair shops, and DIYers. (welcome to visit the official website to view)At the same time, we also represent other brands such as. FOXWELL, LAUNCH, AUTOPHIX, OBDPROG ect. If there are any after-sales or pre-sales messages that can be sent to us, we will promptly handle them and provide satisfactory solutions. If you are satisfied with our product or our service, please leave. ATV, Heavy Duty/Commercial, Motorcycle, Passenger Vehicle. Ultrasonic Injector Cleaner and Tester. Ultrasonic Cleaning; ldle Speed Test.Medium Speed Test; High Speed Test. Accelerating Test; Variable Speed Test. Leakage Test; ldle Spray Volume. Medium Spray Volume; High Spray Volume. LED Display, Pressure Gauge, Glass Tubes.